Technical Article

-

Thin-Ply Carbon Diaphragm Technology: A Material Innovation Enhancing Loudspeaker Efficiency and High-Frequency Extension

Composite Sound's Thin-ply Carbon Diaphragm (TPCD) is an innovative material used in the body of speakers. The Swedish company's vision is to use its precisely designed sound diaphragm to achieve the desired sound quality. The key is to use the innovative weaving techniques of thin film carbon fiber to create the performance of the sound membrane.

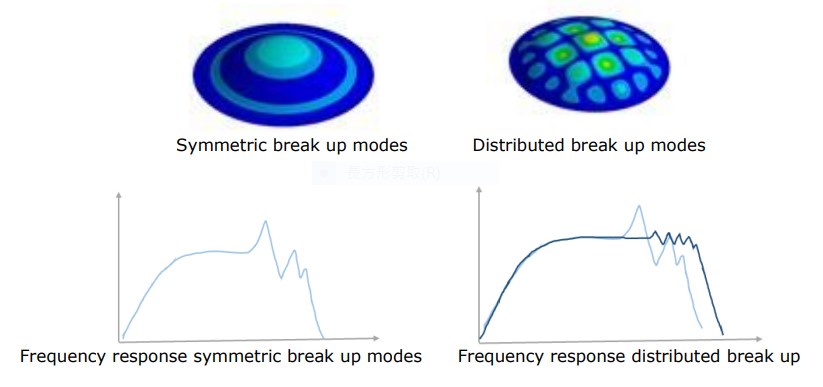

> Traditional speaker diaphragms use isotropic materials, such as metal, paper, or plastic, which have consistent properties in all directions and produce symmetrical segmented motions (modals).

> Using TPCD as a material, symmetric segmentation motions can be eliminated and replaced by small, regional, and dispersed segmentation motions.

> As a result, large peaks and valleys in the frequency response are smoothed and replaced by smaller ones, resulting in a smoother curve and a more natural sound quality.

Kingstate with Composite Sound will develop high-sensitivity speakers using thin film carbon fiber (TPCD) bodies.

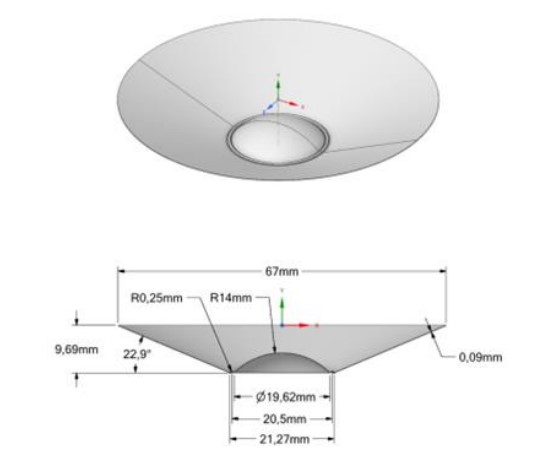

Figure 1, the dimension of cone for prototype tooling Figure 1, the dimension of cone for prototype toolingComposite Sound develops sample molds based on the body dimensions designed by Zhifeng (Figure 1), provides samples with several different structures for Zhifeng to assemble speakers, and tests their sound characteristics to confirm which structure can achieve the expected effect.

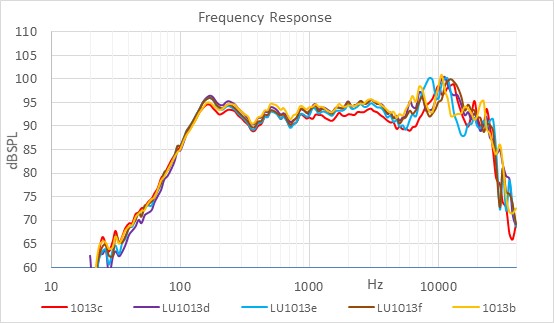

The dimensions of the speaker unit are 85mm long x 85mm wide x 43.35mm high. The sample test and comparison results in Figure 2, confirm the subsequent adjustment direction of the sample.

Figure 2. Speaker test comparison frequency response curve composed of the first batch of samplesKingstate's first goal is to create a speaker with the highest efficiency possible, and the second is to have a wide effective frequency range, especially high-frequency extension.

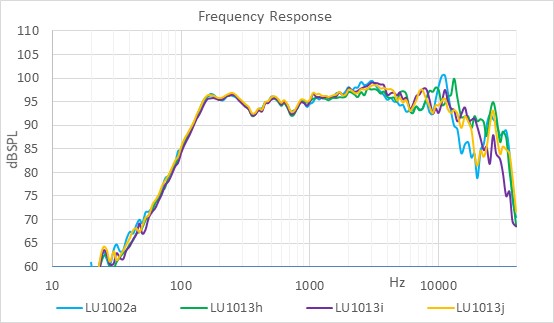

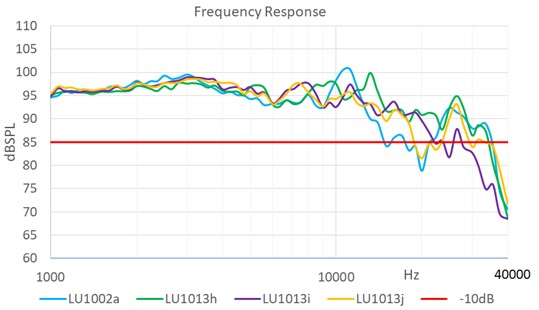

Therefore, the next samples mainly focus on the extension of high frequencies. Figure 3 is the frequency response curve.

Figure 3 Frequency response curve of the second sampleFigure 4 enlarges the curve and adds a horizontal line with the average sound pressure minus 10DB, which can confirm the sample with the best high-frequency extension.

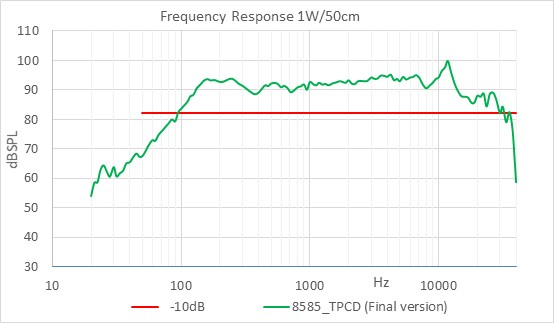

Figure 4 enlarges the curve to confirm the optimal high-frequency extension frequencyThe photo below shows the final version of the sample. Composite Sound will fine-tune the TPCD body of the final sample a version that can be mass-produced later.

From the curve in Figure 5, we confirm that the high frequency can extend to 31 KHz.

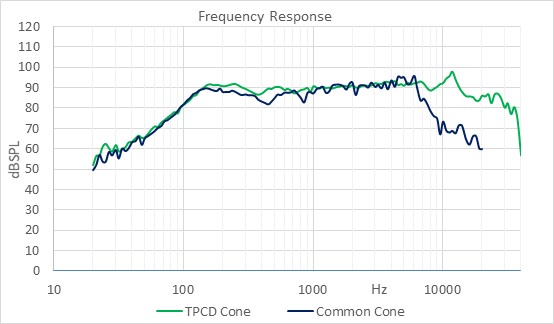

Frequency response curve of the final sampleWe also replaced the final version of the sample with a commonly used body for comparison with thin film carbon fiber (TPCD). The picture below is a photo of a general body speaker.

From Figure 6 we can see that the high-frequency extension of a speaker using a normal body is only about 7 KHz.

Figure 6 Comparison between thin film carbon fiber (TPCD) and general fiberUsing thin film carbon fiber (TPCD) as the body is 3DB higher than that of an 85x85mm speaker using a general body. If the frequency of the average sound pressure is increased to 20 KHz, the average sound pressure of the thin film carbon fiber (TPCD) can achieve an average sound pressure higher than 5DB. This innovative material can indeed be used to develop speakers with high efficiency and excellent high-frequency extension.

RFQ

RFQ