-

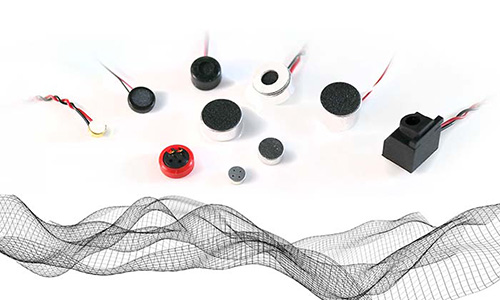

Discover the Secrets of Sound: ECM Hi-SNR Microphones

Our pursuit of sound has never stopped in an era of rapid technological advancement. Whether it's the catchy melody of music or clear voice communications, we aspire to capture the most authentic and moving sounds. And in pursuing sound quality, ECM Hi-SNR microphones are your best partners.

-

Receiving Path Fr Simulation

KINGSTATE has COMSOL Multiphysics Software and high-speed workstations. In the early stage of product development, the 3D/Rubber holder/Microphone parameters of the product mechanism can be input the COMSOL system to simulate the frequency response of the microphone's tunnel path. In the COMSOL system, set the Microphone/Rubber holder and related parameters. After the setting is finished, the COMSOLrt calculates the result.

-

Rubber Holder Design

The microphone is sensitive, usually between the PCB and the panel. It must be closely matched with the panel and airtight buffer material to ensure that the sound will only enter the microphone diaphragm from the microphone sound hole, not other paths. At the same time, it is necessary to provide the diameter and length of the receiving tunnel to avoid resonance frequency falling within the working frequency range. Therefore, besides the essential characteristics of the microphone. The rubber holder will also be a necessary part of achieving the best microphone record characteristics of the product. General recommendations for rubber holder and mechanism design are shown in Fig.2.1 &2.2.

-

Mic Airtight Structure Design

The key to tightly matching the microphone rubber holder and the mechanism is a rubber ring. It can avoid receiving the pressure wave signal from the internal speaker of the product, which causes the DSP to process AEC poorly and makes the product have too many sounds during the phone calls. The echo or distortion phenomenon will decrease the communication quality. Therefore, to achieve airtightness of the rubber ring, the product structure must also give a certain pressure, so the rubber ring can fully interfere with the panel to achieve broadband airtight isolation performance. The AEC test items could pass easier when doing voice quality testing.

-

Hands-Free Car Mic Module Design

A hands-free communication system for cars has been developed to avoid the danger of drivers having to hold the phone while driving. Drivers can speak to the microphone module directly. It can be divided two categories: front-mounted and after-mounted markets. The front-mounted microphone module is mainly installed in the roof map lights; the speaker is the existing speaker system in the car; the after-mounted type is commonly clipped to the sun visor or fixed behind the steering wheel. Most of the products are equipped with speakers; both types of AEC functions are required to avoid excessive echo during a call in the car, which will affect the quality of the call. The microphone module for the vehicle is shown in Fig.4.1

-

Uni-directional Mic Structure Design

ECM has three types of directivities. According to its polar pattern, it can be divided Omni-Directional/Uni-Directional/Noise Cancelling. The Omni-Directional microphone is commonly used around the world, but the usage rate of the noise-canceling type is low. When it is necessary to eliminate the noise in the rear direction, the Uni-Directional Mic is usually selected. Its receiving directivity waveform is similar to a heart shape. Uni-microphone traditionally used in car hands-free calls/ headset Boom microphone/ telephone headset Boom microphone/ conference call system, to reduce the noise of microphone with an angle in 180 degrees, the attenuation of the directivity at 1KHZ with an angle 180 degrees is generally up to 15dB, which can meet general consumer noise reduction purposes (Fig.5.1).

-

Wind Noise-resistant Microphone Design

When the microphone is used outdoors, the wind often affects it to make the microphone diaphragm produce noise. Because wind-shear noise is a low-frequency pressure wave, it will significantly cause the microphone to the diaphragm to move to the limit, and it is easy for the microphone to enter the non-linear working area. The microphone output produces a clipping or distorted signal, degrading the call's quality. To reduce the occurrence of this phenomenon, the microphones of consumer products are usually not like professional equipment. They use bulky windshield equipment to filter out wind-shear noise. We usually put a sponge as noise-canceling material that is placed in front of the microphone's sound hole so that it can be filtered and also attenuate the wind shear simultaneously (Fig.6.1)

-

AEC Optimized Design

Communication products are usually equipped with microphones and speakers. When making a call, the microphone will receive the sound signal from the speaker and enter the system through the microphone again, causing the system to generate echoes that interfere with the call. To eliminate the system whistling sound, it is generally necessary to cooperate with the DSP to effectively eliminate it. The microphone can adopt a uni-microphone to reduce the signal from the rear speaker. The microphone must be as far from the speaker as possible, and the two should not be installed on the same plane. (Fig.7.1)

-

IPX7 Waterproof Structure Mic Design

Many outdoor products need a waterproof function, especially the parts of sound components, such as microphones and speakers, which require a waterproof structure design to ensure that the products will not malfunction after water enters. The general waterproof grade can be divided nine levels; the more common waterproof levels are IPX5, IPX6, and IPX7, of which IPX7 must withstand 30 minutes at 1m underwater of work without damage.

RFQ

RFQ