Rubber Holder Design

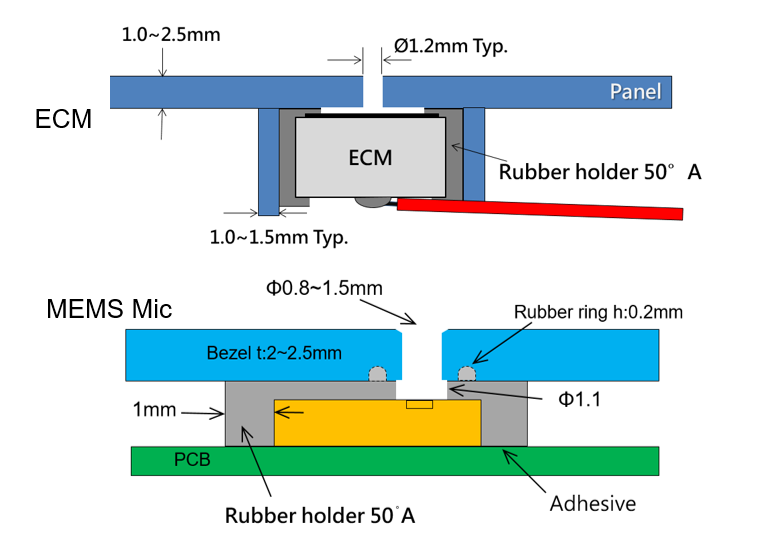

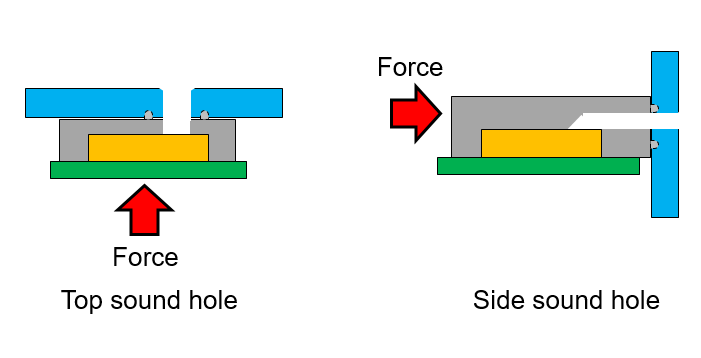

The microphone is sensitive, usually between the PCB and the panel. It must be closely matched with the panel and airtight buffer material to ensure that the sound will only enter the microphone diaphragm from the microphone sound hole, not other paths. At the same time, it is necessary to provide the diameter and length of the receiving tunnel to avoid resonance frequency falling within the working frequency range. Therefore, besides the essential characteristics of the microphone. The rubber holder will also be a necessary part of achieving the best microphone record characteristics of the product. General recommendations for rubber holder and mechanism design are shown in Fig.2.1 &2.2.

The material of the rubber holder will also affect the sound insulation characteristics. Generally, we will choose Shore 50A for the silicon rubber holder. In addition to better airtightness, it can absorb vibration and noise from the housing or PCB. At the same time, it gives appropriate interference force to the rubber ring. It could meet the airtightness requirement at >15dBSPL.

Check next: Mic Airtight Structure Design.

RFQ

RFQ