-

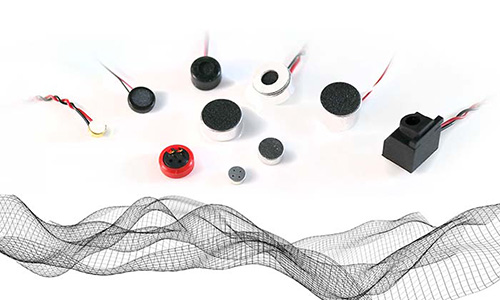

Discover the Secrets of Sound: ECM Hi-SNR Microphones

Our pursuit of sound has never stopped in an era of rapid technological advancement. Whether it's the catchy melody of music or clear voice communications, we aspire to capture the most authentic and moving sounds. And in pursuing sound quality, ECM Hi-SNR microphones are your best partners.

-

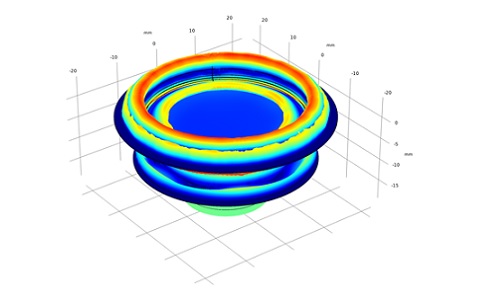

Resonance frequency simulation

Whether it is a Piezo buzzer or Magnetic buzzer, a resonant chamber or cavity is needed to increase the SPL of the product itself. Let's use a guitar for example: if the guitar has only strings without the body, it would be difficult to hear the sound. The sound is amplified through a resonating body.

-

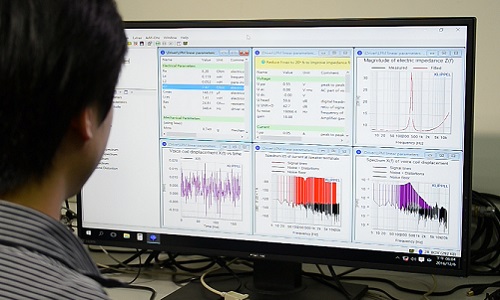

Receiving Path Fr Simulation

KINGSTATE has COMSOL Multiphysics Software and high-speed workstations. In the early stage of product development, the 3D/Rubber holder/Microphone parameters of the product mechanism can be input the COMSOL system to simulate the frequency response of the microphone's tunnel path. In the COMSOL system, set the Microphone/Rubber holder and related parameters. After the setting is finished, the COMSOLrt calculates the result.

-

Pressure Acoustic

COMSOL Multiphysics can build a method to quickly evaluate a receiver's performance in the pressure field of the IEC 318 standard. The IEC 318 standard is the type 1 artificial ear, defined as simulating the acoustic load of the human ear under no leakage conditions. Its frequency bandwidth of application is from 100Hz to 4KHz. The sound pressure level and impedance versus frequencies in the pressure field can be calculated in advance to see if requirements need to be met.

-

Magnetic Circuit

Proper magnetic circuit design directly impacts sensitivities and cost when creating a successful speaker. Finite Element Analysis (FEA) tools can be used to find the best structure for arranging magnets and low-carbon steels, saving time and costs. This approach verifies all required parameters before making the real samples.

-

The Structure of the Soundhole

The sound hole design will also affect the frequency and SPL (but the chamber design still must be a priority step). There are several points for designing a sound hole: The larger sound hole will raise the frequency, and the smaller one will lower it. When the sound hole is not in the middle of the buzzer, the frequency will shift lower. SPL will get lower if the sound hole is designed to be different shapes rather than a circle type.

-

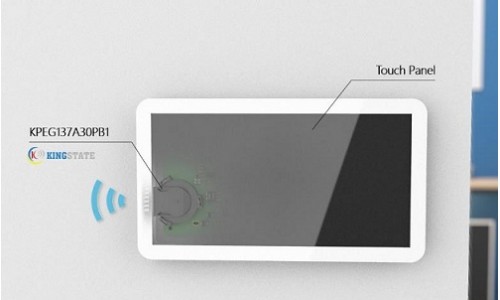

VoIP Phone

VoIP is a more advanced and reliably emerging technology for communication, replacing traditional communication, which is an irreversible trend. VoIP integrates the Internet and conventional communication technologies daily life. Kingstate also has powerful simulation technology to help customers analyze and improve their products. According to the application conditions and needs of customers' products, Kingstate can complete the design based on the speakers' selection and the speaker box's appearance.

-

Rubber Holder Design

The microphone is sensitive, usually between the PCB and the panel. It must be closely matched with the panel and airtight buffer material to ensure that the sound will only enter the microphone diaphragm from the microphone sound hole, not other paths. At the same time, it is necessary to provide the diameter and length of the receiving tunnel to avoid resonance frequency falling within the working frequency range. Therefore, besides the essential characteristics of the microphone. The rubber holder will also be a necessary part of achieving the best microphone record characteristics of the product. General recommendations for rubber holder and mechanism design are shown in Fig.2.1 &2.2.

-

Driver study

The force factor (BL), the mass (weight) of moving parts, the cone's stiffness, and the suspension system's compliance all shape how a speaker sounds. An obvious requirement, such as high sensitivity, deep bass, or low distortion… will give the direction for driver design or the modifications to fine-tune. Driver designers first arrange the key parameters and later balance them with others to produce qualified speakers.

-

Mic Airtight Structure Design

The key to tightly matching the microphone rubber holder and the mechanism is a rubber ring. It can avoid receiving the pressure wave signal from the internal speaker of the product, which causes the DSP to process AEC poorly and makes the product have too many sounds during the phone calls. The echo or distortion phenomenon will decrease the communication quality. Therefore, to achieve airtightness of the rubber ring, the product structure must also give a certain pressure, so the rubber ring can fully interfere with the panel to achieve broadband airtight isolation performance. The AEC test items could pass easier when doing voice quality testing.

-

Optimizing Leakages

Virtual reality attracts people’s attention again, and Metaverse has recently become a hot topic. Acoustic designs for a virtual reality device usually involve pressure or near-field acoustics. Here is an example of a near-field acoustic that reveals how to extend the bass for such a small speaker by designing the proper leakages in its enclosure.

RFQ

RFQ